cnc hinged belt chip conveyor

Class:

Product Center

Summary:

- describe

-

- 商品名称: cnc hinged belt chip conveyor

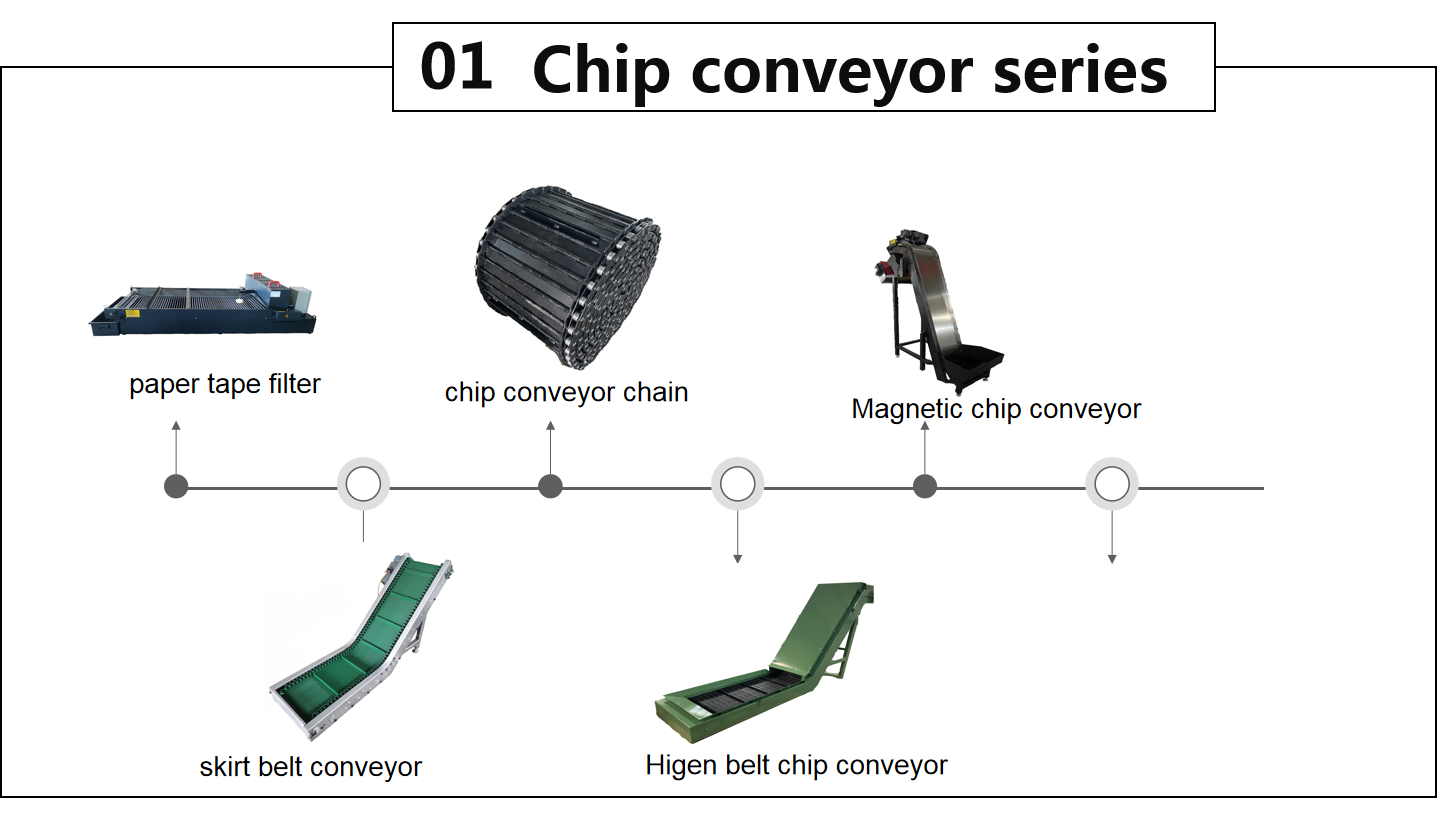

The cnc hinged belt chip conveyor is a machine mainly used to collect various metal and non-metal scrap generated by the machine and transfer the scrap to the collection vehicle. It can be used in conjunction with the filter water tank to recycle various coolants. Chip conveyors include scraper chip conveyors, chain plate chip conveyors, magnetic chip conveyors, screw chip conveyors, and skirt belt conveyors.

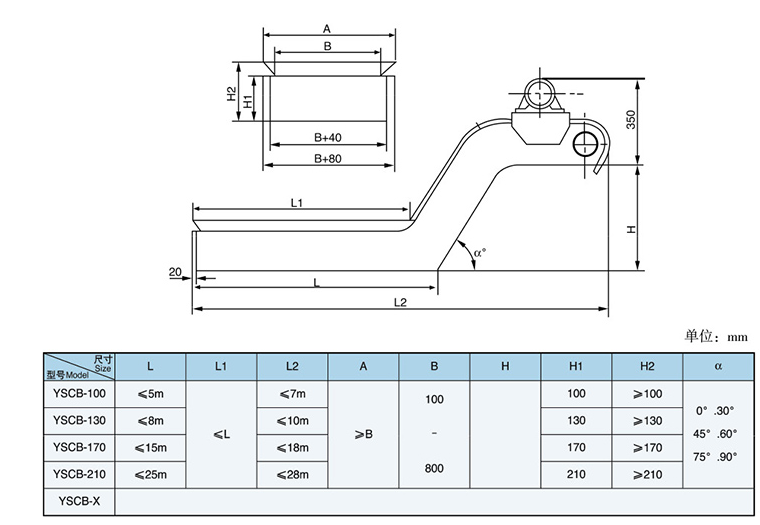

select size

The cnc hinged belt chip conveyor excellent tool for automatic chip conveying is small in size and high in efficiency; It is the most suitable matching model for CNC, NC and industrial machinery. The diversified width of the chain plate provides excellent matching elasticity and effective application. The integrally formed chain plate assembly features high strength, precise coordination, stable, quiet, and compact bump design, which can effectively prevent debris from adhering and increase the ability to remove debris. Torque limit setting effectively reduces damage caused by improper operation.

Product Description

The cnc hinged belt chip conveyor maximum adsorption amount of each group of magnetic materials is fixed, and the chip removal amount can be changed according to the conveying speed and the spacing of each group of magnetic materials. It mainly transports magnetic conductive broken chips, debris, and powder chips with a length of less than 50mm. Widely used in CNC machine tools, modular machine tool production lines, machining centers, and other cutting machine tools, magnetic chip conveying can be combined with other forms of chip removal machines, filters, to meet the different requirements of the host machine, with cooling oil conveying effects not ideal. The overall dimensions and coolant tank of each part can be designed and manufactured according to different cutting machines.

Hinge belt chip conveyors

Hinge belt chip conveyors reliably and efficiently handle machine tool chips, helping you eliminate excessive maintenance and downtime. Tank cleanout frequency can be extended from daily to weekly or even quarterly with chip conveyors, reducing your labor cost and improving machine uptime. Using a hinged steel belt conveyor, chip conveyors easily handle hot chips, wet or dry chips, borings, turnings and other scrap material.

Other products

- A range of belt pitches to fit most machine tool applications

- Proven roller block design for longer chain life

- Robust overload protection for the drive to extend motor life

- Hardened component option available for applications involving abrasive materials

welcome to contact us

- Hinged belt conveyor

- Chip conveyor

- Cnc conveyor

- cnc chip conveyor

Related Downloads

chip conveyor.pdf

Related products

The anti vibration mount is an indispensable and important part of the production line. It is placed under the machine to support the weight of the machine and has the function of shock absorption. It is commonly used in CNC machine tools to attenuate the vibration of the machine itself, reduce the transmission of vibration force, it will prevent the introduction of vibration force, and can also adjust the level of the machine tool. Widely used in various processing equipment, food machinery production lines.

The cnc hinged belt conveyor chain is an important part of the chip conveyor. It mainly produces carbon steel with blackened treatment, and stainless steel materials can be selected to make it stronger and prolong the service life. The surface can be made of different styles, such as convex surface, flat surface, etc.

The main body of the steel cable drag chain is composed of chain plates, support plates, shaft pins and other components, so that there is no relative movement or distortion between the cable or rubber tube and the steel cable drag chain . High, strong rigidity, not easy to deform, easy to install, easy to disassemble, especially this product adopts high-strength wear-resistant material, alloy copper as the shaft pin, which improves the wear resistance of your poor, more flexible bending, smaller resistance, lower It can reduce the noise, so as to ensure that it will not deform or sag after long-term use.

Oil mist collector purifier filter is an industrial environmental protection equipment mainly used to collect pollutants such as oil mist, water mist, or dust generated during the production of purification machines. The oil mist recovery device can absorb and purify about 99% of harmful substances in the mechanical processing environment, playing a role in protecting the health of workers and extending the service life of equipment. Although there are currently no strict regulations in China regarding the use of oil mist recyclers for processing equipment operating in closed environments during the processing process, the installation of Oil mist collector purifier filter has been listed as an industry regulation in developed countries such as Europe and America. Therefore, the installation of oil mist recovery devices has become a historical trend.

The cantilever control panpel hmi box support arm system is made of high-quality anodized aluminum profiles and aluminum die-casting corner parts. It has a simple appearance design and a stable structure. The anodized aluminum profile on the surface is easier to wipe, and always keeps the box as bright as new. The cantilever box is widely used in CNC Installation of various human-machine interfaces and accessories on machine tools, assembly lines and special equipment, with cantilever or support systems.

The steel telescopic cover is equipped with elastic gaskets at the end of each layer of steel plate, which can clean the surface of the steel plate during movement. The Steel telescopic cover can be used horizontally and vertically, and the maximum running speed can reach 60m/min. Various shapes can be designed according to user requirements, such as: flat plate type, arched, round, etc.

Online Message

If you have any questions, please contact us in time and we will give you feedback as soon as possible