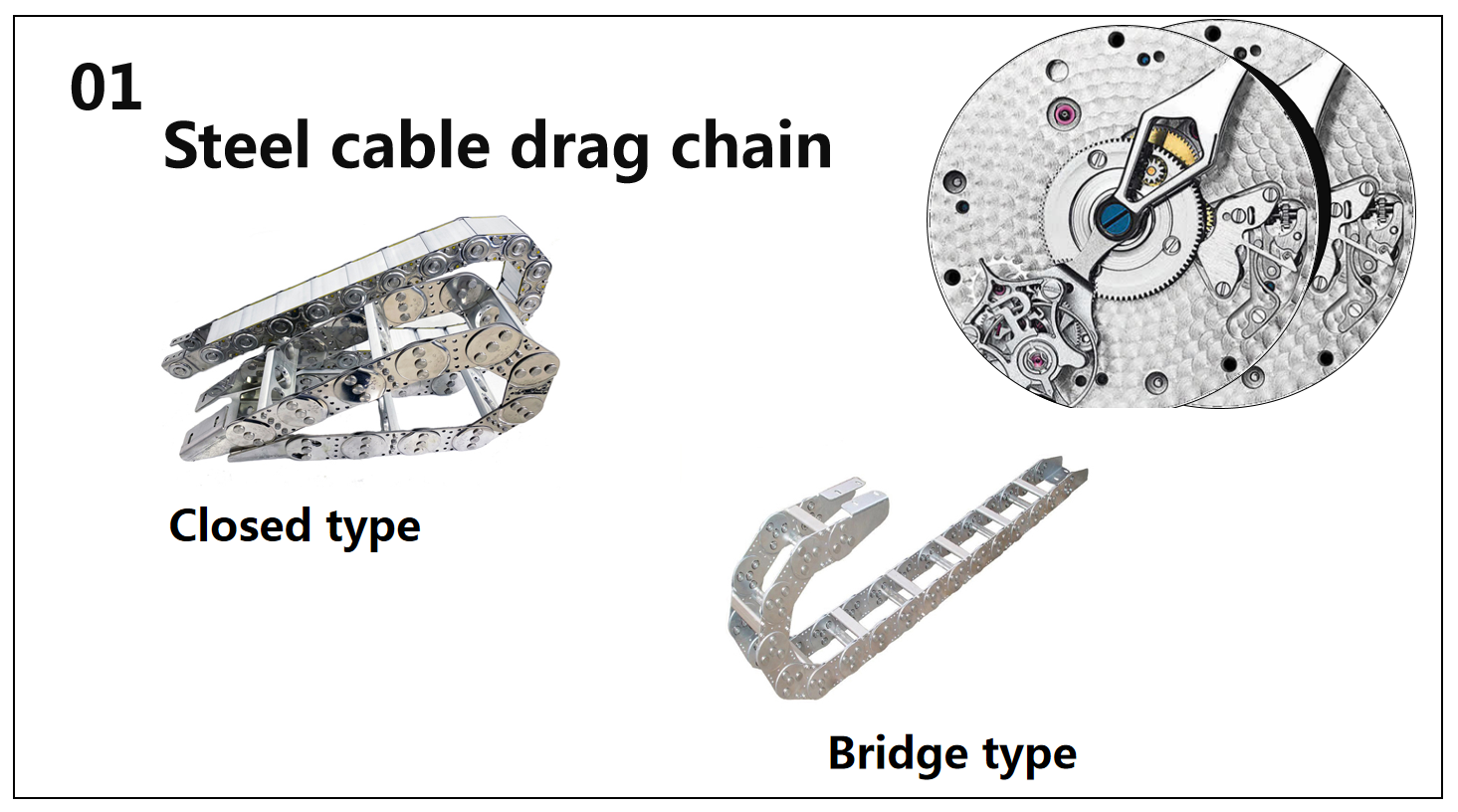

Steel cable drag chain

Class:

Product Center

Summary:

- describe

-

- 商品名称: Steel cable drag chain

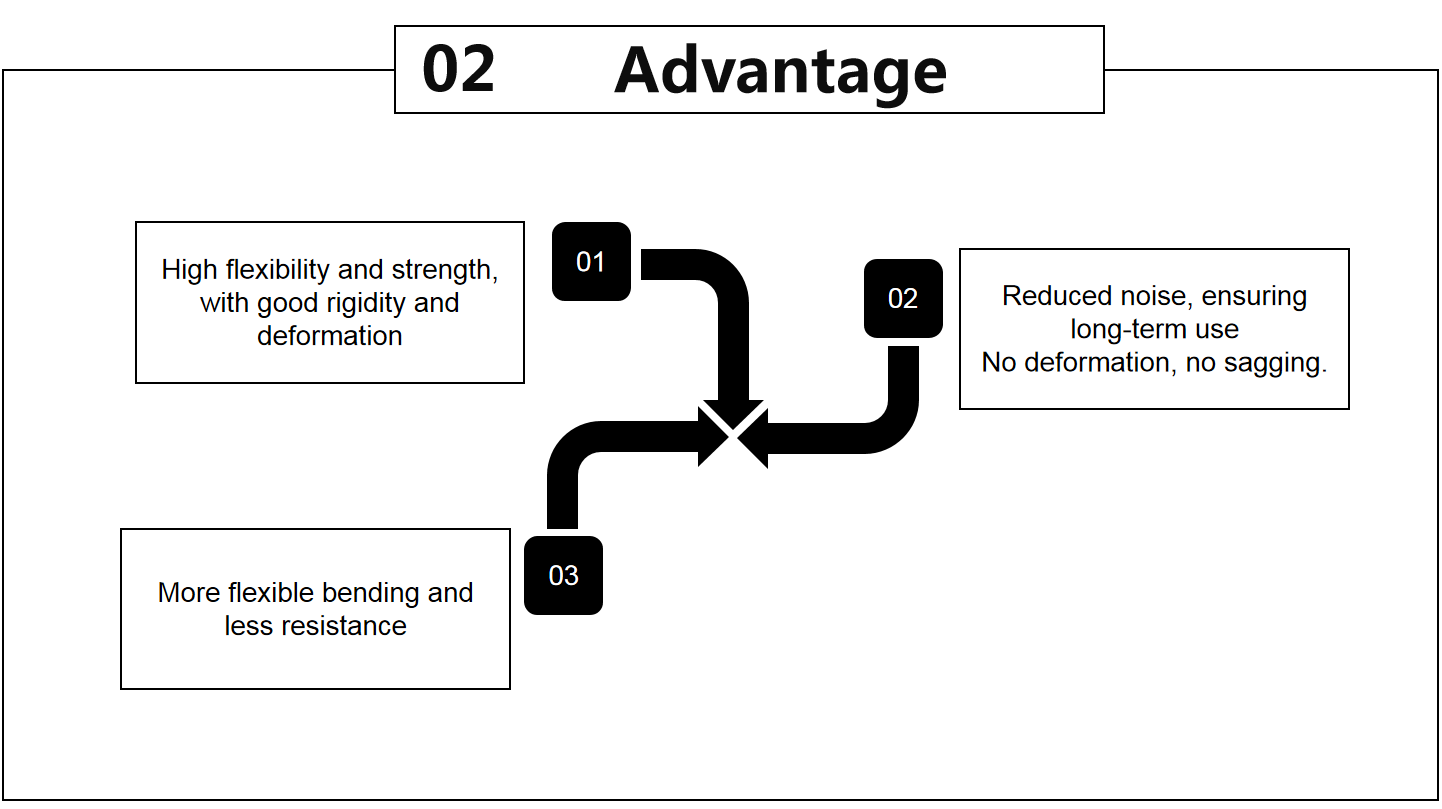

The main body of the steel cable drag chain is composed of chain plates, support plates, shaft pins and other components, so that there is no relative movement or distortion between the cable or rubber tube and the steel cable drag chain . High, strong rigidity, not easy to deform, easy to install, easy to disassemble, especially this product adopts high-strength wear-resistant material, alloy copper as the shaft pin, which improves the wear resistance of your poor, more flexible bending, smaller resistance, lower It can reduce the noise, so as to ensure that it will not deform or sag after long-term use.

select size

Product Description

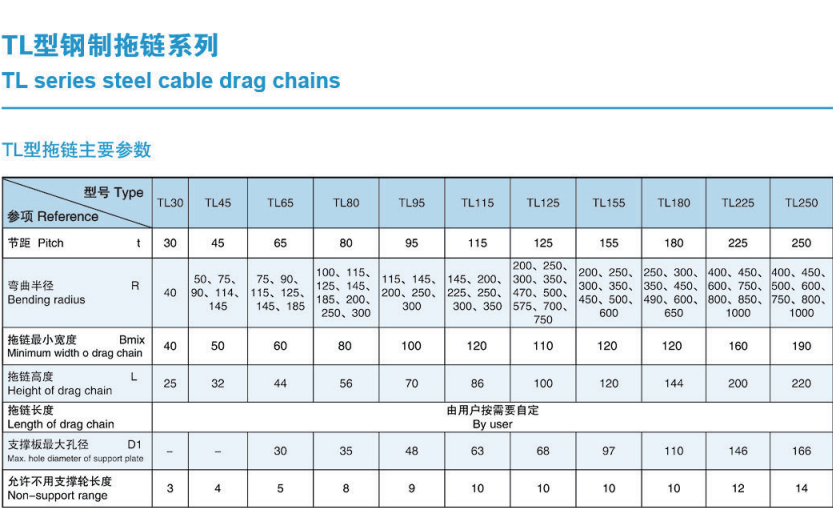

The type steel drag chain has a maximum travel span of 32 meters. Suitable for all transmission modes. Can be lengthened and shortened at will. Furthermore, the changing bending radius can be obtained by changing the pin axis.The support plate digram of the drag chain is 50mm to 600mm, and the interval between the hole and the hole is 5mm.The height of the chain plate, which is the height of the support plate, is maximized by the cable

Diameter determination, the maximum operation of the machine tool, such as the width of the drag chain exceeds 300mm, the length of the drag chain exceeds 4m for stability reasons, should consider to increase the size of the drag chain. The bending radius shall be selected according to the maximum diameter of the cable and shall be 10 times the diameter of the cable. The bending radius can be selected from 50-600mm according to the given table, and a smaller radius can be selected accordingly.

Steel cable drag chain material

Carbon steel/stainless steel 304/316L +aluminum

Type

Bridge type/totally enclosed type

Pitch

45/65/80/95/115/125/155/180/225/250

Bending radius

50-1000

Other products

welcome to contact us

- Steel drag chain

- Steel cable drag chain

- Steel cable wire track

Related Downloads

Steel cable drag chain.pdf

Related products

plastic cable drag chain wire track are divided into plastic drag chains, engineering drag chains, steel aluminum drag chains, steel drag chains, bridge type fully enclosed drag chains, bridge type inner open cover drag chains, silent drag chains, heavy-duty drag chains, assembly drag chains, integral drag chains, convenient open end drag chains, bridge type outer open cover light drag chains, engineering plastic drag chains, plastic drag chains, etc. (1) The plastic cable drag chain wire track is shaped like a tank chain and consists of numerous unit links that rotate freely between them. (2) The inner height, outer height, and pitch of the same series of drag chains are the same, and there are different options for the inner width and bending radius R. (3) The unit chain link is composed of left and right chain plates and upper and lower cover plates. Each section of the drag chain can be opened, making it easy to assemble and disassemble without the need for threading. After opening the cover plate, cables, oil pipes, gas pipes, water pipes, etc. can be placed in the drag chain. (4) Separaters can also be provided to separate the space within the chain as needed.

The cnc hinged belt conveyor chain is an important part of the chip conveyor. It mainly produces carbon steel with blackened treatment, and stainless steel materials can be selected to make it stronger and prolong the service life. The surface can be made of different styles, such as convex surface, flat surface, etc.

The cnc hinged belt chip conveyor is a machine mainly used to collect various metal and non-metal scrap generated by the machine and transfer the scrap to the collection vehicle. It can be used in conjunction with the filter water tank to recycle various coolants. Chip conveyors include scraper chip conveyors, chain plate chip conveyors, magnetic chip conveyors, screw chip conveyors, and skirt belt conveyors.

The anti vibration mount is an indispensable and important part of the production line. It is placed under the machine to support the weight of the machine and has the function of shock absorption. It is commonly used in CNC machine tools to attenuate the vibration of the machine itself, reduce the transmission of vibration force, it will prevent the introduction of vibration force, and can also adjust the level of the machine tool. Widely used in various processing equipment, food machinery production lines.

Oil mist collector purifier filter is an industrial environmental protection equipment mainly used to collect pollutants such as oil mist, water mist, or dust generated during the production of purification machines. The oil mist recovery device can absorb and purify about 99% of harmful substances in the mechanical processing environment, playing a role in protecting the health of workers and extending the service life of equipment. Although there are currently no strict regulations in China regarding the use of oil mist recyclers for processing equipment operating in closed environments during the processing process, the installation of Oil mist collector purifier filter has been listed as an industry regulation in developed countries such as Europe and America. Therefore, the installation of oil mist recovery devices has become a historical trend.

The cantilever control panpel hmi box support arm system is made of high-quality anodized aluminum profiles and aluminum die-casting corner parts. It has a simple appearance design and a stable structure. The anodized aluminum profile on the surface is easier to wipe, and always keeps the box as bright as new. The cantilever box is widely used in CNC Installation of various human-machine interfaces and accessories on machine tools, assembly lines and special equipment, with cantilever or support systems.

Online Message

If you have any questions, please contact us in time and we will give you feedback as soon as possible