Hinged belt conveyor chain

Class:

Product Center

Summary:

- describe

-

- 商品名称: Hinged belt conveyor chain

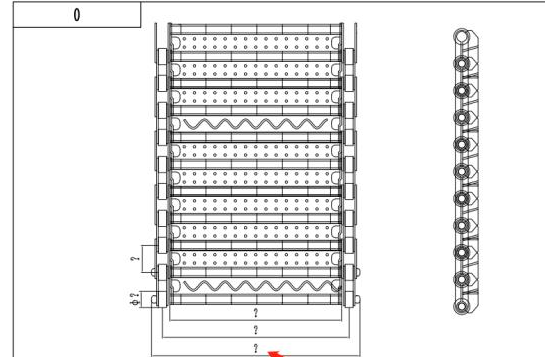

The cnc hinged belt conveyor chain is an important part of the chip conveyor. It mainly produces carbon steel with blackened treatment, and stainless steel materials can be selected to make it stronger and prolong the service life. The surface can be made of different styles, such as convex surface, flat surface, etc.

select size

The conveyor chain it makes structure simple and reduces the cost greatly, more convenient for installation and maintenance. Long service life: the traction chain consists of long pitch, sleeve rolling chain, each parts of chains is made of alloy steel,and processed by heat treatment, so it's very wear-resistant, the part of conveying and the weight of material will be borne by bearing parts, Chains no longer carry weight and it reduces the abrasion. The process layout is settled by many sections horizontal and inclined combination

The conveyor chain One or both pulleys are powered, moving the belt and the material on the belt forward. A powered pulley is called a drive pulley, while an unpowered pulley is called an idler wheel. Belt conveyors have two main industrial categories; general material handling, such as the moving boxes in factories, bulk material handling, such as used for transporting large quantities of resources and agricultural materials, such as grain, salt, coal, ore, sand, covered soil, etc.

Product Description

The conveyor chain consists of traction chain,loading chain and the hopper of positive lap or opposite lap, the three parts are free loading and unloading.The bearing roller with rolling bearings and the rolling friction replaces the sliding friction, it decreases the running resistance by 55%-65%, which greatly reduces the power and energy consumption of the conveyor.

Other products

Hinged belt conveyor chain material

Carbon steel /stainless steel 201/304

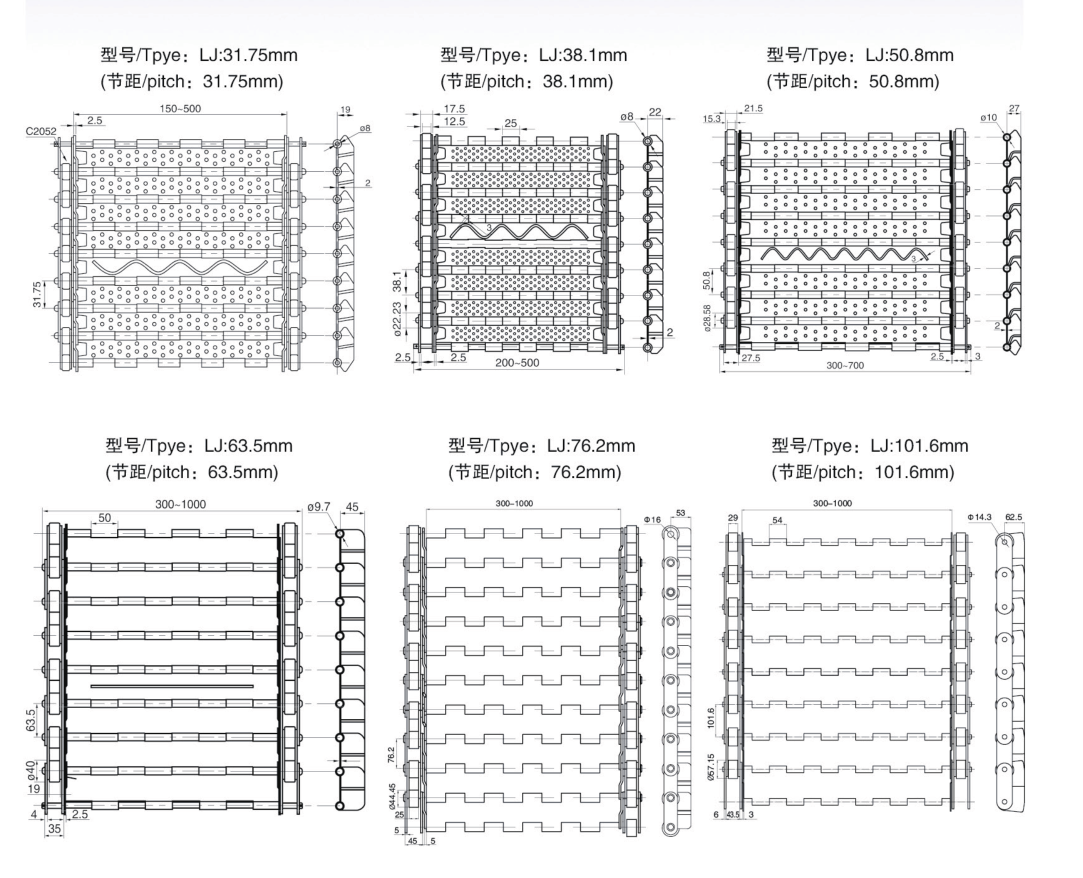

Pitch

31.75/38.1/50.8/63.5/76.2/101.6

Width

Can be customized

Surface

Bump/hole/flat

Sidewall

Welding/flexible type

welcome to contact us

- Hinged belt conveyor chain

- Chip conveyor chain

- Cnc conveyor chain

Related Downloads

链条Chip conveyor chain.jpg

Related products

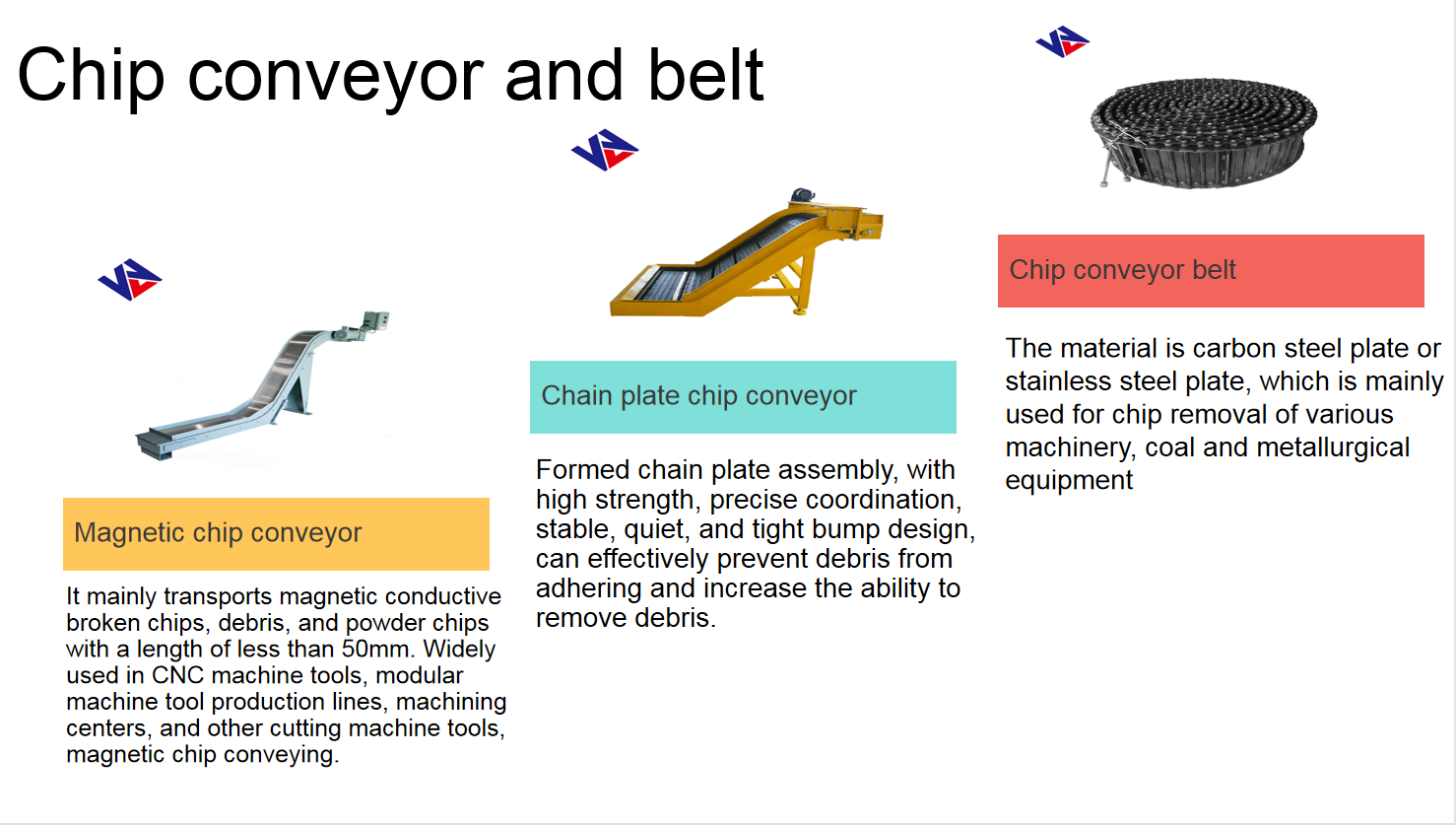

The cnc hinged belt chip conveyor is a machine mainly used to collect various metal and non-metal scrap generated by the machine and transfer the scrap to the collection vehicle. It can be used in conjunction with the filter water tank to recycle various coolants. Chip conveyors include scraper chip conveyors, chain plate chip conveyors, magnetic chip conveyors, screw chip conveyors, and skirt belt conveyors.

plastic cable drag chain wire track are divided into plastic drag chains, engineering drag chains, steel aluminum drag chains, steel drag chains, bridge type fully enclosed drag chains, bridge type inner open cover drag chains, silent drag chains, heavy-duty drag chains, assembly drag chains, integral drag chains, convenient open end drag chains, bridge type outer open cover light drag chains, engineering plastic drag chains, plastic drag chains, etc. (1) The plastic cable drag chain wire track is shaped like a tank chain and consists of numerous unit links that rotate freely between them. (2) The inner height, outer height, and pitch of the same series of drag chains are the same, and there are different options for the inner width and bending radius R. (3) The unit chain link is composed of left and right chain plates and upper and lower cover plates. Each section of the drag chain can be opened, making it easy to assemble and disassemble without the need for threading. After opening the cover plate, cables, oil pipes, gas pipes, water pipes, etc. can be placed in the drag chain. (4) Separaters can also be provided to separate the space within the chain as needed.

The anti vibration mount is an indispensable and important part of the production line. It is placed under the machine to support the weight of the machine and has the function of shock absorption. It is commonly used in CNC machine tools to attenuate the vibration of the machine itself, reduce the transmission of vibration force, it will prevent the introduction of vibration force, and can also adjust the level of the machine tool. Widely used in various processing equipment, food machinery production lines.

The plastic cnc bellows protective cover mainly have three material : Nylon cloth prevent oil dust water , High temperature cloth , fireproof cloth . plastic cnc bellows protective cover have been widely used in CNC machine tools, electronic equipment, stone machinery, glass machinery, door and window machinery, injection molding machines, robotic arms, lifting and transportation equipment, automated warehouses, and protect guide etc. Any shape can be cusomized .

The cantilever control panpel hmi box support arm system is made of high-quality anodized aluminum profiles and aluminum die-casting corner parts. It has a simple appearance design and a stable structure. The anodized aluminum profile on the surface is easier to wipe, and always keeps the box as bright as new. The cantilever box is widely used in CNC Installation of various human-machine interfaces and accessories on machine tools, assembly lines and special equipment, with cantilever or support systems.

The steel telescopic cover is equipped with elastic gaskets at the end of each layer of steel plate, which can clean the surface of the steel plate during movement. The Steel telescopic cover can be used horizontally and vertically, and the maximum running speed can reach 60m/min. Various shapes can be designed according to user requirements, such as: flat plate type, arched, round, etc.

Online Message

If you have any questions, please contact us in time and we will give you feedback as soon as possible